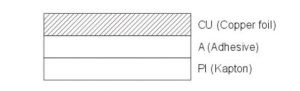

FPC is the abbreviation for flexible printed circuit. Flexible circuit board is also called flexible circuit board (FPC) for short. It is mainly composed of CU (Copperfoil) (ED or RA copper foil), A (Adhesive) (acrylic and epoxy resin thermosetting adhesive) The circuit board composed of PI (Kapton, Polyimide) (polyimide film) has many advantages such as high wiring density, thinness, space saving, weight reduction and high flexibility. It has a very wide range of applications in production and life, and The market is still expanding. Mainly used in notebook computers, mobile phones, medical and other products.

Structure of FPC:CU+A+PI

CU (Copperfoil): E.D. and R.A. copper foil

Cu copper layer, copper skin is divided into RA, RolledAnnealed Copper and ED, Electrodeposited. The two have different characteristics due to different manufacturing principles. ED copper has low manufacturing cost but is fragile when doing Bend (bending) or Driver (drilling) The copper face is easy to break. RA copper has high manufacturing cost but good flexibility, so the FPC copper foil is mainly RA copper.

A (Adhesive): Acrylic and epoxy resin thermosetting adhesive

Adhesive is two major systems: Acrylic and Epoxy.

PI (Kapton): Polyimide (polyimide film)

PI is the abbreviation of Polyimide, called Kapton in DuPont, and the unit of thickness is 1/1000inchlmil. The characteristics are thin, high temperature resistance, and good electrical insulation.

FPC production process

The production process of flexible circuit boards is more complicated, involving many processes, from mechanical processing to ordinary chemistry to photochemistry. Electrochemistry. Thermochemistry and so on, but also include the knowledge of computer-aided design CAM, which shows the complexity of the process. Because the flexible circuit board production process is a non-continuous form, any error in any link will result in production shutdown or a large number of scraps. If the printed circuit board is scrapped, it cannot be recycled and reused. Let’s take a look at the specific production process.

Single-sided rigid printed circuit board: → single-sided copper clad laminate → blanking → (washing, drying) → drilling or punching → screen printing circuit anti-etching pattern or using dry film → curing inspection and repairing board → etching copper → forward resistance Etching, drying → scrubbing, drying → screen printing solder mask graphics (commonly used green oil), UV curing → screen printing character marking graphics, UV curing → preheating, punching and shape → electrical opening, short circuit test → scrubbing , Drying → pre-coated soldering anti-oxidant (drying) or spraying tin hot air leveling → inspection packaging → finished products leave the factory.

Double-sided rigid printed board: →Double-sided copper clad laminate → blanking → stacking → CNC drilling through holes → inspection, burr scrubbing → chemical plating (through hole metallization) → (full board electroplating of thin copper) → Inspection, scrubbing, screen printing of negative circuit patterns, curing (dry film or wet film, exposure, development) → inspection, repairing → circuit pattern plating → tin electroplating (anti-corrosive nickel/gold) → printing material (photosensitive film) →Etching copper→(removing tin)→cleaning and scrubbing→screen printing solder mask graphics commonly used thermal curing green oil (photosensitive dry film or wet film, exposure, development, thermal curing, commonly used photosensitive thermal curing green oil)→cleaning, drying →Screen printing, marking characters and graphics, curing→(spray tin or organic solder mask)→shape processing→cleaning, drying→electrical on-off test→inspection and packaging→the finished product leaves the factory.

Features of flexible circuit board

- Reduce the size of the application product, save space, greatly reduce the weight, increase the function, and reduce the cost.

- It has high flexibility, can be wired three-dimensionally, and the shape can be changed according to space constraints.

- Can be folded without affecting signal transmission, anti-static interference.

- High and low temperature resistance, flame resistance.

- Stable chemical changes, high stability and reliability.

- Provide more related solutions for related products, which can reduce assembly man-hours and errors, and increase the service life of related products.

Function of flexible circuit board

- The function of the soft board can be divided into four types, namely lead wire, printed circuit, connector and lead wire of multi-function integrated system

- Connection between rigid printed circuit boards, three-dimensional circuits, movable circuits, high-density circuits

- Printed circuit: high-density thin three-dimensional circuit connector

- Low-cost rigid board connection and multi-action integration system

- Integration of hard board leads and connectors

Application of flexible circuit board

FPC are widely used in commercial electronic equipment, car dashboards, printers, hard disk drives, floppy drives, fax machines, car mobile phones, general phones, notebook computers, cameras, video cameras, CD-ROMs, Hard disks, watches, computers, cameras, medical equipment and other electronic products and equipment.

PCB assembly/SMT

PCB assembly/SMT PCB Manufacturing

PCB Manufacturing Components Sourcing

Components Sourcing PCB design

PCB design