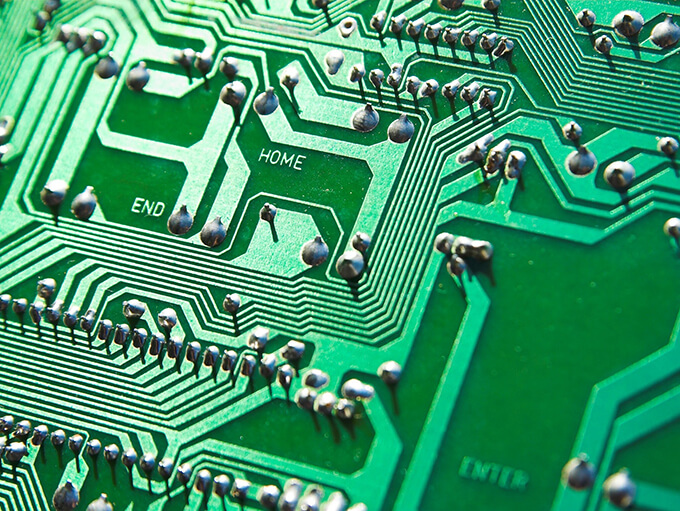

PCBA processing belongs to precision processing. Incorrect operation will cause cracks, breaks, open circuits and bending fractures of components and connectors, which will eventually lead to damage to components and PCBA. To avoid these situations, the following rules must be observed during PCBA processing:

-

Keep the working environment clean

The working environment consists of two parts, one is the workshop area and the other is the workbench. It must be clean and tidy. There must be no food, beverages and other items, and ashtrays, cigarettes and other items must not be placed. Smoking is prohibited.

-

Reduce PCBA processing steps

The processing steps of PCBA are not that complicated. On the contrary, PCBA processing manufacturers emphasize that the less the better. It is best to reduce the PCBA processing steps to a minimum to reduce risks. At the same time, when operating, you must cooperate with gloves, don’t disturb, use it directly, it is easy to hurt your hands and cause injury. In addition, gloves should be changed frequently to avoid affecting operation.

-

Do not operate with bare hands

Grease in the hands will reduce the solderability of the components. Therefore, direct manipulation with bare hands or fingers is not allowed, thereby reducing weld ability.

-

Do not use hand cream or silicone cleaners

Both of these conditions will lead to reduced solderability and failure of the coating to adhere. Therefore, please do not use it. This is the basic rule of workshop operation and should be followed by any employee.

-

PCBA cannot be superimposed

During the operation, some novices may stack PCBA boards due to unskilled operations, which can easily damage the PCBA boards, so it is strictly forbidden to use them. The correct method is to place it in a specially configured dedicated bracket.

-

The type of sensitive components should choose the appropriate logo

Among PCBA components, there are some sensitive components, such as EOS/ESD. These components are very sensitive, so appropriate markings must be selected. In addition, static electricity should be controlled during operation.

The above six points are the rules that must be followed during PCBA processing. They seem troublesome, but in fact, they are the basic requirements to ensure a smooth PCBA processing workflow.

PCB assembly/SMT

Finetech PCBA processing advantages

-

Strength guarantee

▪ SMT workshop: It has imported placement machines and multiple optical inspection equipment, which can produce 4 million points per day. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪ DIP production line: There are two wave soldering machines. Among them, there are more than ten old employees who have worked for more than three years. The workers are highly skilled and can weld all kinds of plug-in materials.

-

Quality assurance, high cost performance

▪ High-end equipment can paste precision shaped parts, BGA, QFN, 0201 materials. It can also be used as a model for mounting and placing bulk materials by hand.

▪ Models and large and small batches can be produced

-

Rich experience in SMT and soldering of electronic products, stable delivery

▪ Accumulated services to thousands of electronic companies, involving SMT chip processing services for various types of automotive equipment and industrial control motherboards. The products are often exported to Europe and the United States, and the quality can be affirmed by new and old customers.

▪ Delivery on time, normal 3-5 days after the materials are complete, and small batches can also be shipped on the same day.

-

Strong maintenance ability and perfect after-sales service

▪ The maintenance engineer has rich experience and can repair the defective products caused by all kinds of patch welding, and can ensure the connection rate of each circuit board.

▪ 24-hour customer service staff will respond at any time and solve your order problems as quickly as possible.

PCB assembly/SMT

PCB assembly/SMT PCB Manufacturing

PCB Manufacturing Components Sourcing

Components Sourcing PCB design

PCB design