Air purifiers, also known as “air cleaners”, air fresheners, and purifiers, refer to decoration pollution that can absorb, decompose or transform various air pollutants (generally including PM2.5, dust, pollen, peculiar smell, formaldehyde, etc.) , Bacteria, viruses, allergens, etc.), products that effectively improve air cleanliness, are mainly divided into household, commercial, industrial, and building, and are widely used in home, office, medical and industrial fields.

There are many different technologies and media in air purifiers, which enable it to provide users with clean and safe air. Commonly used air purification technologies include: adsorption technology, negative (positive) ion technology, catalytic technology, photocatalyst technology, superstructure light mineralization technology, HEPA high-efficiency filtration technology, electrostatic dust collection technology, etc.; material technologies mainly include: photocatalyst, activated carbon, Synthetic fiber, HEPA high-efficiency material, negative ion generator, etc. Most of the existing air purifiers are of composite type, that is, multiple purification technologies and material media are used at the same time.

What industry does the air purifier belong to?

According to the use function of small household appliances, they can be divided into three categories, namely:

1.Small kitchen appliances: electric kettle, electric hot pot, microwave oven, disinfection bowl, cabinet induction cooker, rice cooker, etc.;

2, household appliances: vacuum cleaners, electric heaters, household water purifiers, air purifiers, electric fans, etc.;

3.Small household appliances for personal life: hair dryer, electric shaver, electric iron, electric toothbrush, etc.

The penetration rate in South Korea has reached 70%, the penetration rate of air purifiers in Europe is 40%, the penetration rate of air purifiers in the United States is 28%, and the penetration rate of air purifiers in Japan is 34%, while the air quality in China is far below the above. In the country, the penetration rate of air purifiers is only 2%.

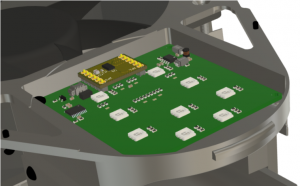

We are now producing air purifiers for a German customer, indoor type. We are responsible for PCB production, component procurement, SMT processing, functional testing, and housing assembly.

This air purifier is divided into 3 parts. Main board, sensor board, battery board. These three parts are combined to form an air purifier.

The main board of this product is a 4-layer board. FR4 material, surface finish lead free HASL, black solder mask and white silk print, thickness is 1.6mm, copper thickness is 1oz per layer. In addition, the sensor board and battery board are all 2-layer PCB, surface finish lead free HASL, 1.6mm thickness, Black solder mask and white silk print.

The overall functional test takes about 30 seconds, and it takes 4 minutes to complete the assembly of an air purifier. Install the motherboard, install the fan and filter, install the battery board, and finally fix the shell with screws.

The difficulty of this product lies in the fixtures made in the SMT process, as well as the wiring and fixtures for testing according to the customer’s functional test instructions.The number of 3K, we need to complete within 1 week. We will use 2 of the 6 SMT lines to mount and assemble in two shifts.

We produced 1,000 units of the first version last year, and this year’s 3K units are upgraded models. As an OEM factory, I feel a lot of responsibility for contacting various customized PCBAs from various countries every day. We are also very interested and happy to do this work and support.

PCB assembly/SMT

PCB assembly/SMT PCB Manufacturing

PCB Manufacturing Components Sourcing

Components Sourcing PCB design

PCB design